- Consulting Tel : 0571-23208118 Email : fts@zjdmxc.com

- CN

We know that the lithium battery in electric vehicles, whether it is the charging process or the discharge process, is actually the movement of lithium ions, and the movement of lithium ions is bound to go through the electrolyte. The charging process is the movement of lithium ions from the positive electrode to the negative electrode, and the discharge process is the movement of lithium ions from the negative electrode to the positive electrode. At low temperatures, due to the deterioration of electrolyte conductivity and other reasons, the capacity of lithium batteries will decline sharply, and at this time, lithium evolution is prone to occur in the negative electrode of the battery, causing in permanent damage to the battery, and the charge and discharge current will also be reduced. In general, the performance and service life of lithium batteries decrease at low temperatures, and the way to reduce the impact of low temperatures is to heat the battery to keep it in a good temperature range.

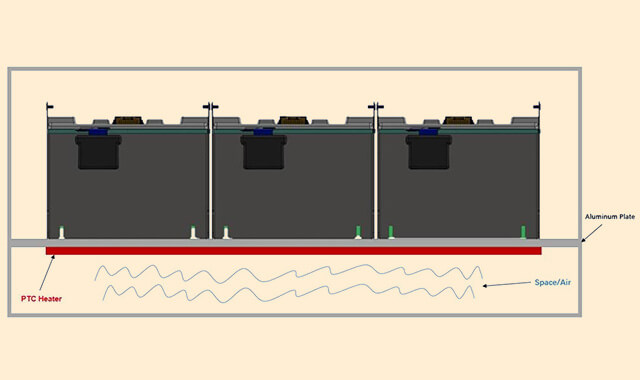

Commercial vehicle case: The heating film is pasted on the aluminum plate, and the heat is transferred to the battery core after the aluminum plate is heated.

Industry Case:

Evaporator heating film

In winter, the water in the evaporator freezes, its volume will expand, which will destroy the internal structure of the evaporator. The water inside the evaporator must be kept at a non-freezing temperature. Therefore, a heating element is in need, and the PTC self-regulating heating film can solve this problem well.

1. PTC heating film is a flexible material, which can perfectly fit on the cylindrical surface of the evaporator, and the direct heat transfer avoids heat waste.

2. The PTC heater can be heated quickly at low temperatures, and the power continues to decline after opening, saving energy.

3. The PTC heating film has been designed and verified, and the protection level has reached IP67 to avoid short circuit leakage caused by condensate water in the evaporator.