- Consulting Tel : 0571-23208118 Email : fts@zjdmxc.com

- CN

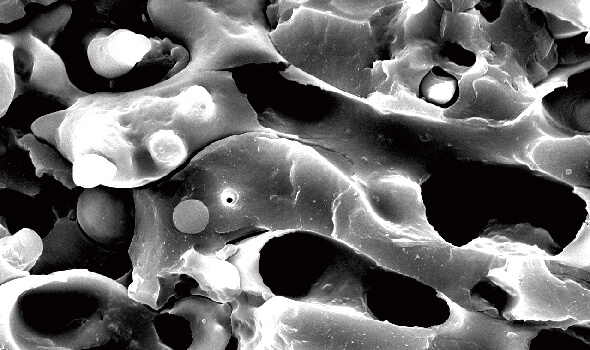

Polymeric Positive Temperature Coefficient Thermistor Material is made from polymeric matrix and soot carbon particles by two-stage mixing. This kind of material has a "temperature memory” function. It adjusts the resistance automatically with temperature changes.When temperature reaches the setting, the resistance change is significant and current decreases markedly. At this point the light current through keeps the thermistor at the temperature and high resistance.When temperature is back to normal, the thermistor shrinks to the original form and links soot carbon particles again, cooling polymeric PTC thermistor soon and returning to the original low resistance. The cycle repeats.

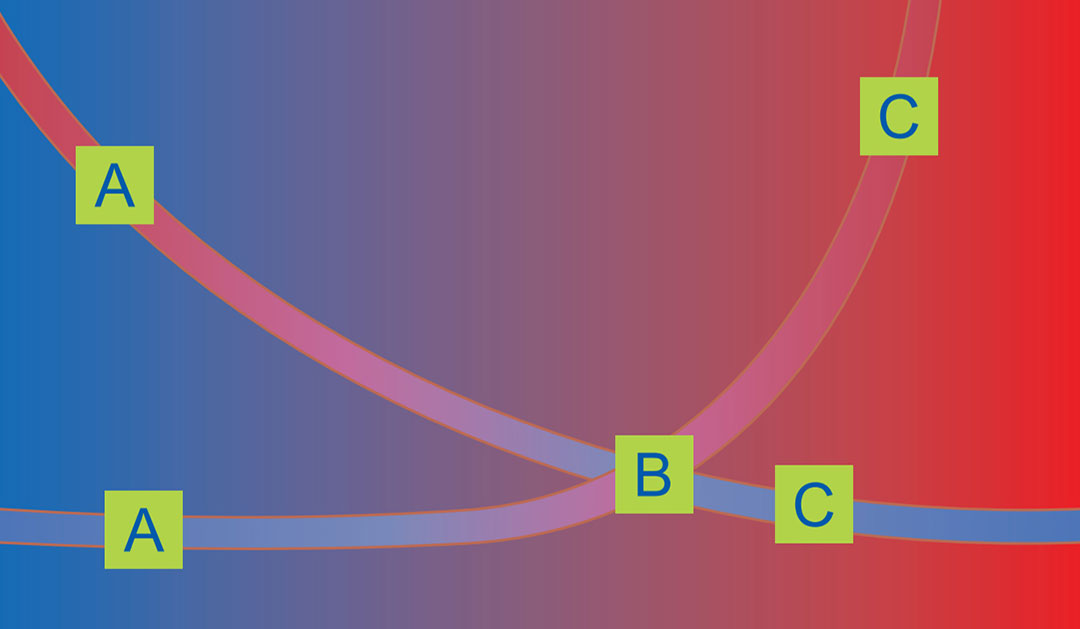

In instances of low temperatures, the conductive molecular links within the nano-heating material embedded in the PTC heating element exhibit tight coupling, resulting in low resistance and high power. Upon the application of power, the thermal movement becomes vigorous, leading to a rapid elevation of surface temperature.

Upon temperature elevation, the conductive molecular chains within the nano-heating material embedded in the PTC heating element undergo elongation due to the influence of the PTC material. This elongation impedes the flow of current, resulting in a gradual reduction of power in the heating element.

Upon reaching the temperature preset by the heating element, the conductive molecular chains experience gradual thermal movement induced by the PTC material. This leads to an infinite resistance state, prompting the PTC to automatically decrease power output, thereby maintaining the surface temperature of the heating element.