- Consulting Tel : 0571-23208118 Email : fts@zjdmxc.com

- CN

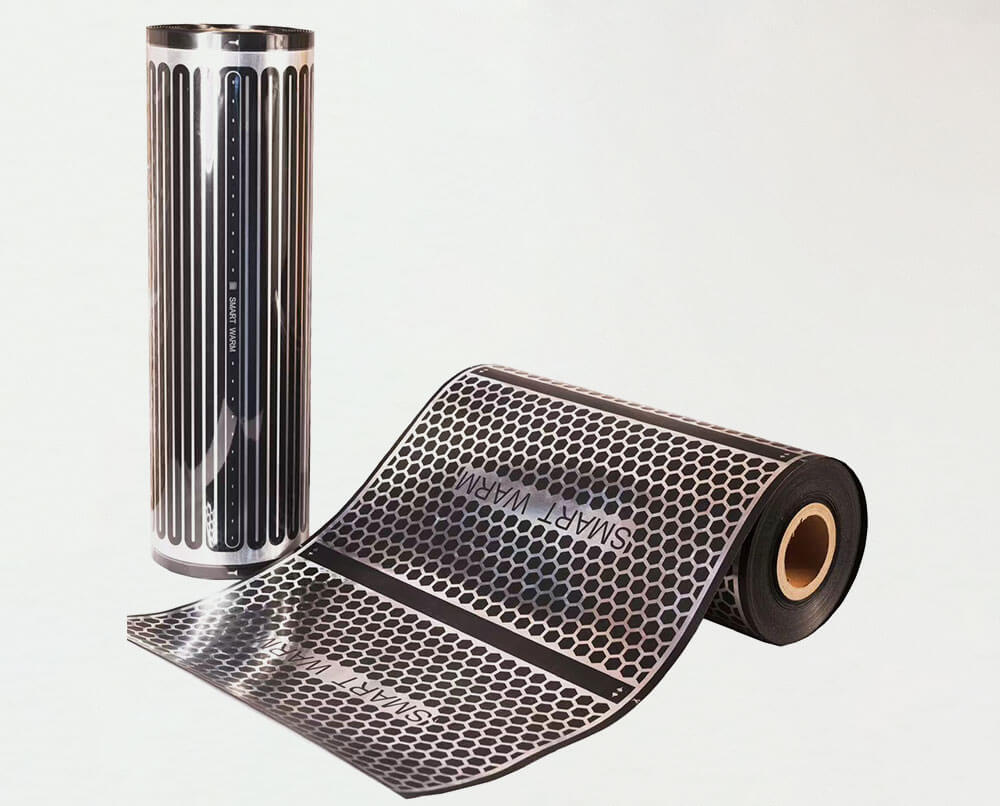

SMARTWARM®The self-limiting heating film are multi-layer structures. The core conductive heating component is a resin-based heating film layer filled with conductive carbon particles. Conductive film and copper finger electrodes are wrapped in the polyimide material used in conventional heaters to provide electrical insulation. In the non-conductive resin matrix material layer of the heating film, electrons move between carbon particles through quantum tunneling to form an electric current. The resistance of the material and the amount of electric current in any area are determined by the spacing between carbon particles, which changes with temperature.

Our electric underfloor heating systems, electric blankets, and household heaters are bringing safe, convenient, clean, and environmentally friendly heating methods to millions of households.

In the field of new energy vehicles, we are focusing on battery thermal management and hydrogen energy, providing customers with safer and more energy-efficient heating solutions.

For the heating of electronic devices, we have a lot of cases and experience, and can provide a variety of products to meet the different needs of customers.

The military assembly field has a higher demand for product stability, and the PTC heating film we developed can provide higher stability.

For the aerospace field, our PTC heating film provides better safety performance for the national and civil aviation industry.

The development of domestic high-end medical devices requires more domestic parts, for this market we have more flexible and safe solutions to meet customer needs.

The PTC heating film we developed has the characteristics of faster heating at low temperatures and self-limiting temperature at high temperatures, and we have greater advantages in the wearable field.