- Consulting Tel : 0571-23208118 Email : fts@zjdmxc.com

- CN

Belonging to the field of electric trace heating technology, existing electric trace heating systems are complex in structure, occupy large spaces, and are difficult and costly to install. The system employs single-core series-connected constant power heating cables. With one control panel controlling the heating cables, the required cross-sectional area and conductivity of the heating cables can be calculated using corresponding formulas based on the length of the pipe to be heated and the required heat output. With a group of power sources and control panels supplying power to the heating cables, the length of the heating cables can reach up to 30 kilometers or even longer, capable of heating pipes exceeding 30 kilowatts in length. This greatly simplifies the structure of the electric trace heating system, offering advantages such as small footprint, simple structure, stable operation, and low construction costs.

We are providing professional, reliable and systematic services to the petrochemical industry, providing electric heat tracing systems with stable operation for 30 years.

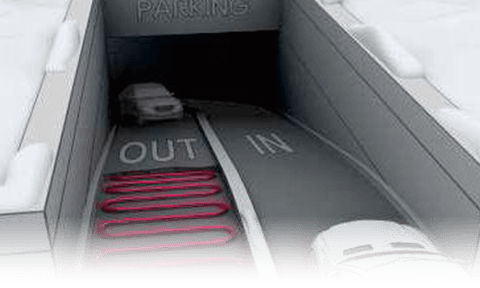

We have a professional team to provide reliable solutions for civil municipal engineering projects such as ice melting and snow melting.